Call for help:+86-571 63256551

Mail us:[email protected]

- Home

-

Products

- EPP machine

- EPS Pre-expander Machine

- Fast Change Mold Type Eps Shape Molding Machine

-

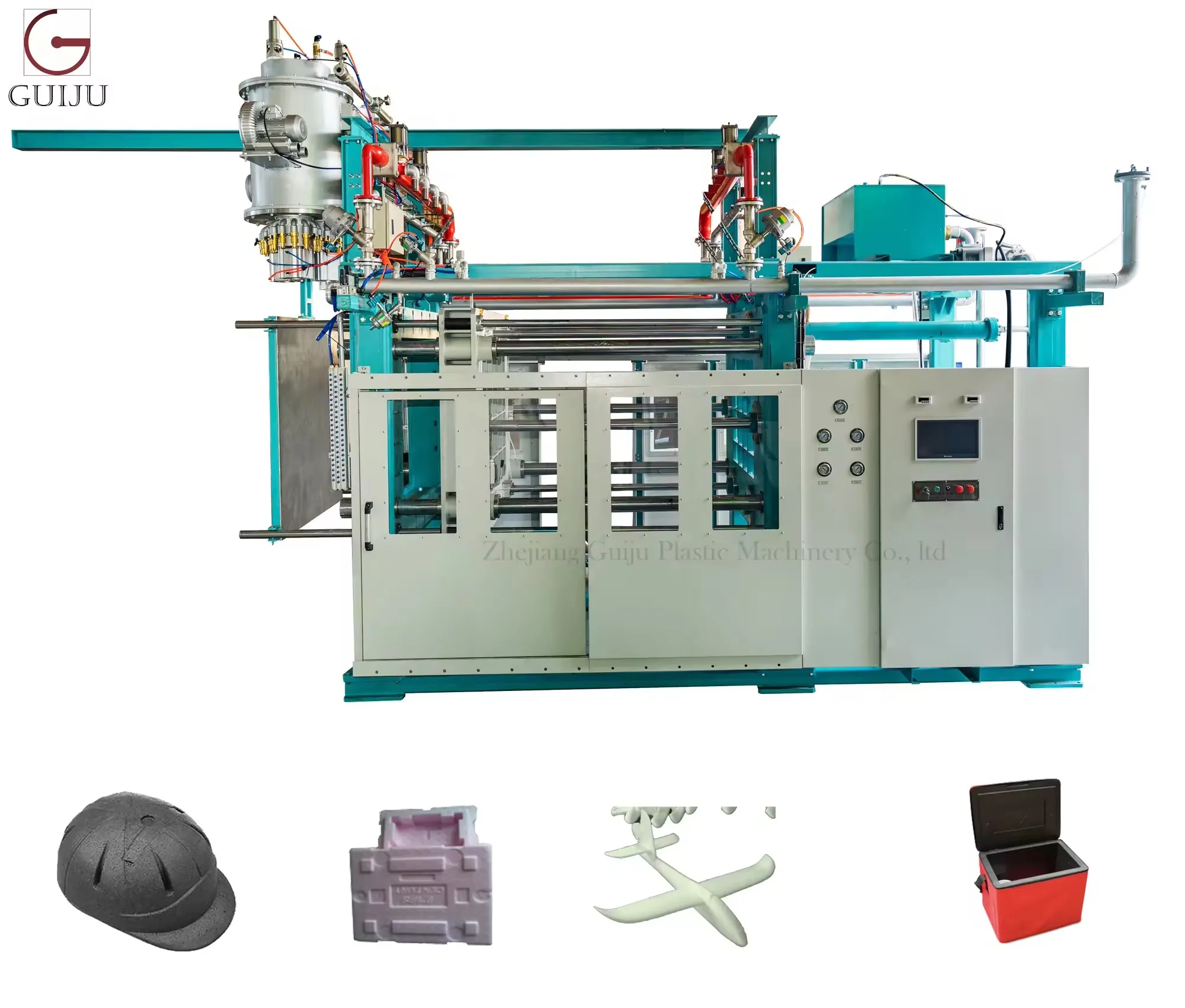

EPS Shape Molding Machine

- EPS foam tray making machine

- ICF block machine

- EPS foam box package making machine

- EPS foam cornice and ceiling tile making machine

- EPS foam hourdis making machine

- EPS foam insert making machine

- EPS foam helmet making machine

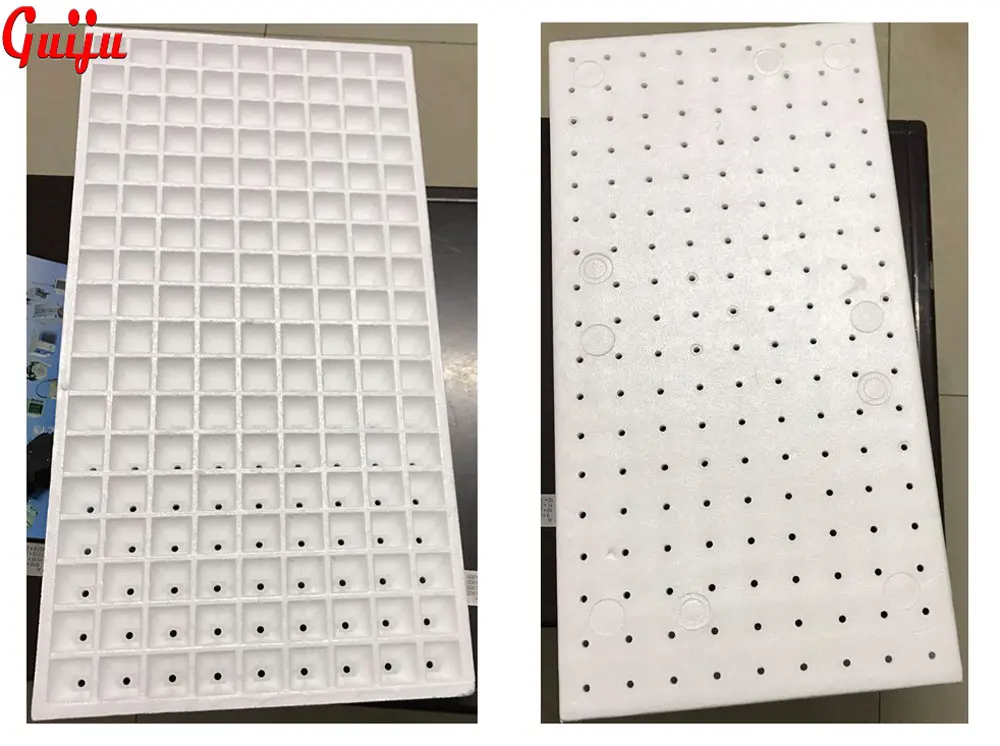

- EPS floor heating sheet making machine

- semi-auto eps shape molding machine

- EPS foam waffle pod making machine

- EPS Block Molding Machine

- EPS Cutting Machine

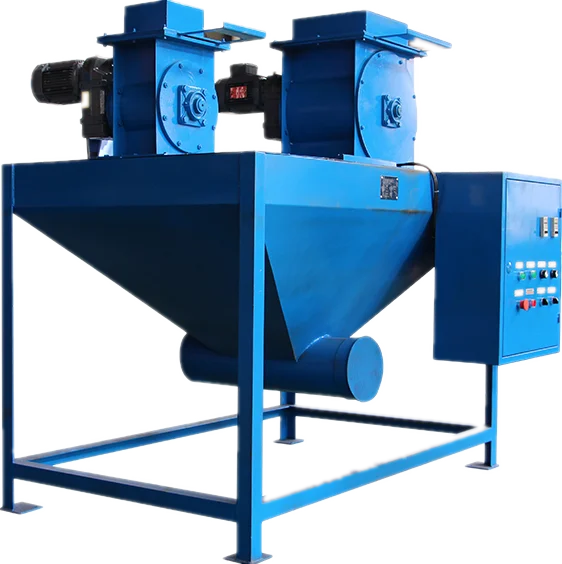

- EPS Recycling System

- EPS mold

- EPS silo

- Spare parts for EPS machine

- Auxiliary equipment for eps machine

- About Us

- News

- Customers Cases

- Videos

- Contact Us

- Home

-

Products

- EPP machine

- EPS Pre-expander Machine

- Fast Change Mold Type Eps Shape Molding Machine

-

EPS Shape Molding Machine

- EPS foam tray making machine

- ICF block machine

- EPS foam box package making machine

- EPS foam cornice and ceiling tile making machine

- EPS foam hourdis making machine

- EPS foam insert making machine

- EPS foam helmet making machine

- EPS floor heating sheet making machine

- semi-auto eps shape molding machine

- EPS foam waffle pod making machine

- EPS Block Molding Machine

- EPS Cutting Machine

- EPS Recycling System

- EPS mold

- EPS silo

- Spare parts for EPS machine

- Auxiliary equipment for eps machine

- About Us

- News

- Customers Cases

- Videos

- Contact Us