- Overview

- Recommended Products

It includes the supporting auxiliary equipment required by the EPS machine, such as boilers, steam tanks, air compressors, air tanks, cooling towers, etc.

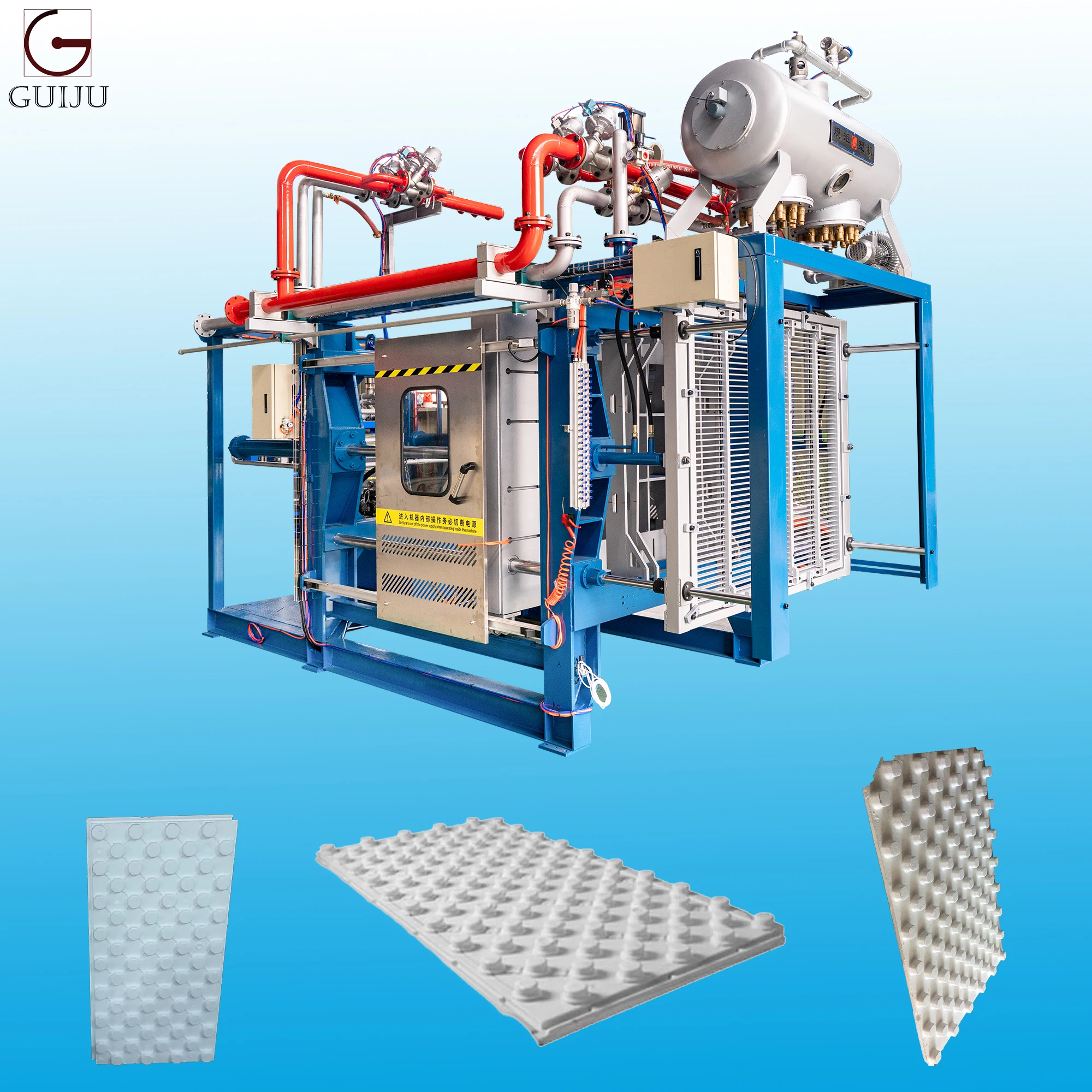

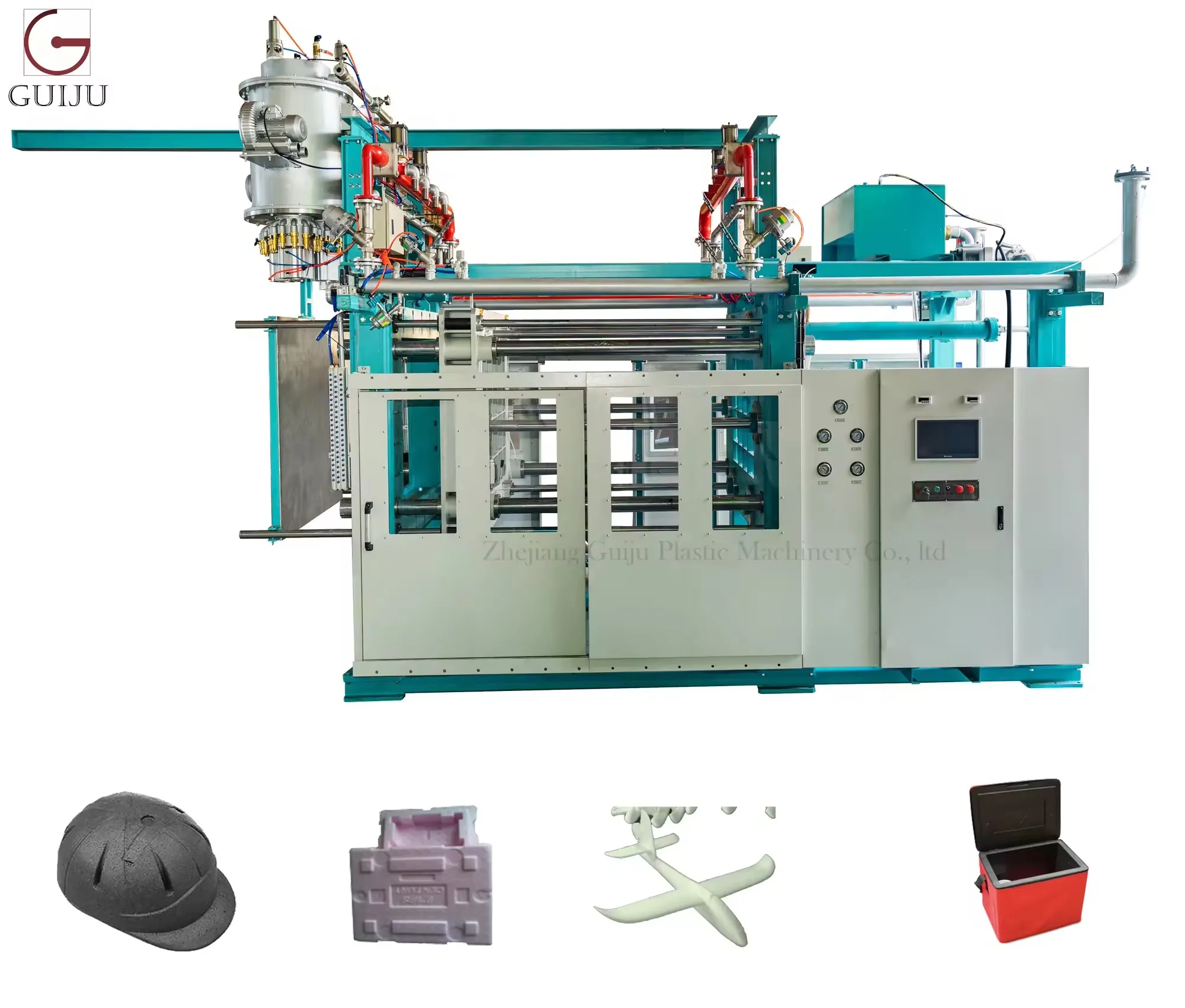

Top sales automatic EPS shape molding machine with vacuum cooling

Technical data

|

Model

|

6m³

|

10m³

|

15m³

|

20m³

|

||

|

Diameter - mm

|

Ø1400

|

Ø1600

|

Ø1800

|

Ø2000

|

||

|

Dimension(mm)

|

5000*1650*2016

|

4000*1450*1762

|

6000*1850*2216

|

6500*2050*2416

|

||

|

Container categories

|

I

|

I

|

I

|

I

|

||

|

Working pressure(Mpa)

|

1.0

|

1.0

|

1.0

|

1.0

|

||

|

Design pressure(Mpa)

|

1.05

|

1.05

|

1.05

|

1.05

|

||

|

Operating temperature(℃)

|

179

|

184

|

184

|

184

|

||

|

Design temperature(℃)

|

181

|

186

|

186

|

186

|

||

|

Medium

|

Saturation steam

|

Saturation steam

|

Saturation steam

|

Saturation steam

|

||

|

Main pressure component material

|

Q345R

|

Q345R

|

Q345R

|

Q345R

|

||

|

Corrosion allowance(mm)

|

1.0

|

1.0

|

1.0

|

1.0

|

||

|

Welded joint coefficient

|

0.85

|

0.85

|

0.85

|

0.85

|

||

|

Full volume(m³)

|

6

|

10

|

15

|

20

|

||

|

Design life(Year)

|

10

|

10

|

10

|

10

|

||

|

Safety valve start pressure(Mpa)

|

1.03

|

1.02

|

1.02

|

1.01

|

||

|

Maximum lifting weight(kg)

|

1170

|

2058

|

2878

|

3159

|

||